Quartz stone is currently a kind of abbreviation of quartz stone plate manufacturers for the plates they produce, because the main component of its plate quartz content is as high as 93%, so it is called quartz stone.

Quartz stone production process

Description of quartz stone process flow

1. Raw material collection: procurement of raw and auxiliary materials such as glass, quartz, and resin.

(1) Resin

(2) Quartz sand

2. Material selection: use fans, iron removal equipment, and manual selection to remove impurities and iron filings in granular raw materials.

3. Batching: After the selection of materials, the materials are transported into the mixing system. The material is fully mixed in a weightless mixer to eliminate material color differences and particle unevenness. After the mixing is completed, it is transported to the corresponding batching silo, and the batching system automatically batches during production.

4. Stirring: Fully stir and mix unsaturated polyester resin, pigments, additives, and granular powder.

5. Cloth: The mixed material enters the cloth cart through the conveyor belt, and then the material is evenly distributed into the fabric mold frame by the cloth truck.

6. Vacuum high-frequency vibration pressure plate: After the cloth is completed, it is transferred to the press equipment and vibrated and pressed under the vacuum condition of -0.1MPa.

7. Heating and curing and shaping: After pressing, the blank is heated into the curing oven at 85-110 °C.

8. Fixed thickness grinding: After the blank is cured, it is cooled and cooled for 24 hours, and enters the thickness fixing equipment for thickness setting.

9. Polishing: After the thickness is fixed, through the 20-head polishing machine, water grinding and polishing. According to different needs, polished to a gloss of 40-70°.

10. Inspection: inspection of the appearance quality of the plate.

11. Cutting plate: use longitudinal and cross-cutting, bridge-cutting machine equipment to cut the product to the required size.

12. Packaging and storage: After the cut products are dried, they are packed and stored in the warehouse.

Quartz stone finished product processing technology

Quartz stone processing is an important part of ensuring the quality of the countertop. No matter how good the quartz stone plate is, quality problems will occur if the strict quartz stone processing method is not followed.

The processing requirements of quartz stone are, in principle, the same as the processing of natural stone, because it is the same as natural hemp stone and granite. Operators who process quartz stone should preferably have experience in processing natural stone, and operators who have processed ordinary artificial stone but have no experience in processing natural stone must be trained before they can work.

Necessary processing tools: multi-functional marble cutting machine (cutting and cutting, edge chamfering), grinding machine (with the special diamond grinding disc, resin grinding disc), cantilever water grinding and polishing machine, gong machine (with quartz stone special gong head), curve data, A clamp, G clamp, small blade, triangle glass fixture, wiring socket, etc.

Special glue: marble glue (white, transparent), quartz special glue (factory formulated), quartz stone special dry glue (factory formulated), curing agent.

Processing program:

Common quartz stone countertop processing edge types:

Processing precautions:

Quartz stone hardness is too high, its plasticity is not as strong as artificial stone, and processing technology is also higher than artificial stone, the following are the processing quartz stone must pay attention:

(1) Connection: Quartz stone connection generally adopts 45-degree splicing. When flattening, the connection surface must be straightened with a straight knife, the docking is seamless before connection, and the color of the glue must be tested before the connection, and the color can be made after the color is no problem.

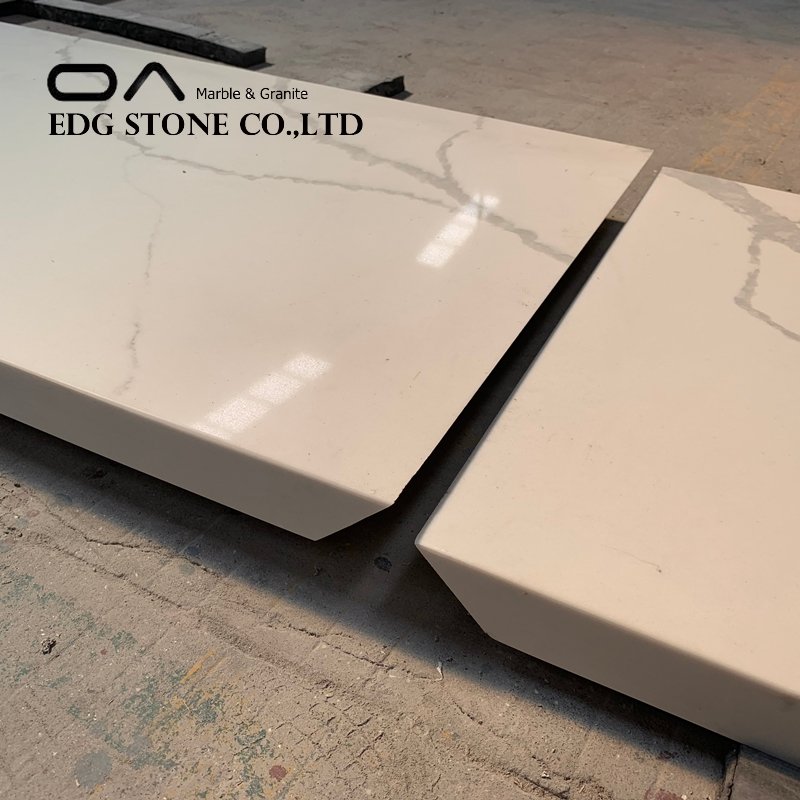

Calacatta quartz tops

The remaining glue at the connector is removed with a small blade after the gel but before it is hardened, and then sanded after the glue is fully hardened, and the grinding range should not be expanded.

After the quartz stone is connected, the splicing will generally have traces like a line, but it is not easy to see without looking carefully, and it does not affect the beauty.

(2) Opening: When opening the furnace hole, there should be a cushion plate at the bottom of the quartz stone plate, which cannot be completely suspended, and the bearing force should be uniform to prevent cracking during the opening process due to uneven force.

Before opening, first, reinforce the four sides and middle of the quartz stone bottom, and then punch holes in the four corners of the furnace hole (the drill bit for drilling must be a high-hardness diamond drill bit, which is available in Yunfu’s stone processing tools and supplies store), and then use a wire cutting machine to cut slowly and evenly into squares, when cutting, the plate can not be cut through at one time, it should be cut in two steps, the first step is to cut 1/3 of the thickness of the plate, and the second step is to cut the plate through to prevent the plate from cracking.

quartz countertops

After the furnace hole is cut square, the four corners of the furnace hole are ground into a circular arc angle with an angle grinder, the radius of the arc is not less than R10mm, and the back of the four corners of the furnace hole is thickened with a small plate of about 120×120mm, and then the angle grinder is ground into a corresponding arc, and the four sides are thickened with quartz stone plates with a width of more than 30mm. In addition, the distance between the furnace hole edge and the rear water edge is not less than 70mm.

(3) Edging and chamfering: use hard diamond water grinding plate, first 50#, then 150#, then 300#; When polishing, start with a 500# water mill, and then use 800#, 1000#, 1500#, 2000# water mill blade in turn.

Note that the diamond water grinding disc must be hard, and must be emphasized to the supplier. The size of the water mill blade is 3 inches or 4 inches, which can be determined according to the needs of users.

(4) Glue use: Before using glue, the glue must be fully stirred evenly. The glue curing agent is the same as an ordinary artificial stone curing agent, and its relationship between the amount of addition and temperature is as follows:

When the temperature is below 10 °C, the amount of curing agent added is 1.5-2% of the glue;

When the temperature is 10 °C–20 °C, the amount of curing agent added is 1% of the glue;

When the temperature is 20 °C–30 °C, the curing agent added amount is 0.5-0.8% of the glue;

When the temperature is above 30 °C, the curing agent added amount is 0.5% of the glue.