The processing method of quartz stone is similar to natural granite, and it has a completely different method from the artificial stone currently on the market. All operations must be coordinated with cooling water. ▌Countertop processing 1. Handling 2. Opening 3. Join 4. Edge processing 5. Opening 6. Cut corner 7. Under counter basin processing 8. 8. Processing of flat table pads Packaging and Transportation 10. On-site construction and installation ▌1. Storage and transportation-It are strictly forbidden for two people to lay the board flat. 1-1 Quartz stone must be stored indoors to avoid sunlight.

Table processing

1. Carry

2. Cutting

3. Join

4. Edge processing

5. Cut out

6. Chamfer

7. Under counter basin processing

8. Processing of flat table pads

9. Packaging and transportation

10. On-site construction and installation

▌1. Storage and transportation-It is strictly forbidden for two people to lay the board flat.

1-1 Quartz stone must be stored indoors to avoid sunlight.

1-2 Use two A-type storage racks, 1.5 meters apart. The bottom is covered with wooden strips, and the boards are evenly and tightly attached to the side plates of the iron frame, and to ensure that each board is tightly pushed against one side and does not exceed 25 boards.

1-3 In order to avoid bending and deformation of the table, do not place the finished product vertically.

1-4 The transportation mentioned here refers to the manual transportation during processing and installation. All the transportation must use the method of standing the board. The two people move the board to the front of the machine or workbench, and then apply force at the same time. Turn it evenly on the machine or workbench. When the back side is facing down, you can slowly drag the plate to adjust its position. When the front side is facing down, it is strictly prohibited to drag the plate to avoid scratching the surface. The principle is placed on the cabinet, when necessary, 3-4 people can work together to complete the operation.

1-5 Three large triangular iron frames (wooden frames) are used for loading of large boards. They are 90 cm apart. The bottom is covered with wooden strips. The length of the wooden strips is equal to the width of the car box to prevent slippage. Make sure that each board is front-to-front and back-to-back. The board must be pushed tightly, and then use soft rope (broadband) to bind the board. The rope passes through the place and is covered with paper to prevent the bumps or damage caused by the sliding of the board due to transportation bumps.

1-6 A pair of triangular wooden frames are used for the loading of finished products. The wooden frames must be fixed to the bottom of the vehicle to prevent sliding. The finished product leans against the wooden frame, placed on both sides, and then tied to the wooden frame with a soft rope (broadband) to prevent the sliding of the transportation bumpy plate.

▌2. Opening-all operations must be coordinated with cooling water

2-1 You must read the drawings before opening the material to avoid size errors, conceive how to open the sheet, be aware of the opening of the material, and the principle of meeting the requirements of the drawings and saving materials.

2-2 Before opening the board, first check whether the remaining materials are suitable, and check whether the colors are consistent, and visually check whether there are defects on the board surface.

2-3 Before opening the material, the board must be carefully checked for color differences. For the board with cracks and defects, it should be clear whether it can be avoided during the processing, and there will be no spots after the completion of the work, which will cause serious economic losses.

2-4 The principle of material utilization is 90%, and the width of the remaining material can exceed 60mm.

2-5 Try to avoid the back-to-back connection. The front edge can be polished and polished after proper bonding.

2-6 It can be used with hand-cutting machine and edge-cutting machine.

2-7 Ensure that 3-5mm expansion gaps are reserved on the wall.

2-8 The cutting speed of cutting is 4m / min.

2-9 After opening the material, check the size of each plate against the drawings. The segment position, auxiliary materials, number, address and joints should be written clearly, and the next process should be explained clearly.

▌3. Join

3-1 The products from the previous process must be inspected for quality, and unqualified products should be rejected.

3-2 You must read this single drawing before bonding the countertops, understand the relationship between the joined countertops and the entire set of countertops, and receive the glue, straight edges, and front edge materials required for the countertop.

3-3 Establish a special person to adjust the color of the glue. The color of the glue should be as close as possible to the color of the board. Before the glue is glued, the team leader must agree that this color matches the countertop before it can be used.

3-4 When using quick-drying glue, it should be added in accordance with the ratio of glue and curing agent specified in the instruction manual. It is strictly forbidden to add a large amount of curing agent to affect the firmness of the joint and the color variation, and strictly control the amount of glue adjustment each time to avoid waste.

3-5 When joining with straight edges, the surface to be pasted is thoroughly cleaned, dried, and flat. Check the flatness of the joint surface on the back of the large board. If necessary, use a corner grinder to finely modify. Clean and dry the bonding surface, evenly apply the same color glue and the bottom of the large panel within 15mm, put the straight edge strip on the glue and rub it left and right, squeeze out the air, use the clamp and the rubber hammer to cooperate, the moderate force will clamp the straight edge strip Align with the big board. Place the clip every 5-10 cm, and remove the overflowing glue after half drying. After the edge strips are bonded (after drying), use the same color glue to connect the same color quartz stone reinforcement to connect the straight edges to the board surface. Finally, use glass glue and other clips to bond the lined wood strips to the board flat (lay flat formula)

The bottom of all fixtures must be clamped under the wooden side of the workbench, and cannot directly touch the smooth surface.

The bottom must be absolutely flat.

3-6 The front edge is joined. First, use quick-drying same-color glue to fix the quartz stone reinforcement, and fix it to the bottom of the board according to the straight-edge adhesive method. After the glue is dry, apply the same color glue to the back of the front edge evenly. With the power of the rubber hammer, the front edge is firmly connected to the reinforced material that has been bonded to ensure the smoothness of the protruding water line and the seamless combination of the gap. When the glue is semi-dry, use a small blade to scrape off the overflowing glue. Finally, use glass glue and clips to bond the lined wooden strips to the board flatly. (Lay flat)

When using a large clamp to clamp the front edge, it is necessary to lengthen the wooden strips on both sides of the board, and it is forbidden for the long clamp to directly contact the two sides of the board.

The bottom must be absolutely flat.

▌4. Edge processing

4-1 The products from the previous process must be inspected for quality, and unqualified products should be rejected.

4-2 The processing of the polygon includes the back wall edge, the straight edge, the bevel edge, the front edge edge, the irregular edge, etc. All the water milling edges are required to be close to the original surface brightness.

4-3 Straight edges such as the back wall, beveled edge, and front edge shall be ground with a edging machine first. If manual edging is used, the linear deviation must be within 0.5mm, which shall be produced in strict accordance with the standards of the system.

4-4 Maintain the inherent shape of the board edge during water milling. The water mill only plays a polishing role and cannot change its shape.

4-5 The edging use from 50, 100, 150, 300, 500, 800, 1000, 2000, 3000 # water milling blades must ensure that each water mill, playing each water mill is completely and thoroughly in place, the standard can use 50 #, 150 # , 500 #, 1000 #, 2000 # and 3000 # 6 water mills, each water mill should be given enough water to prevent burning the surface especially during fine grinding. The rotation speed of the mill is above 4000r.p.m.

4-6 When sanding, the bottom of the table must be straight, and the height of multiple tables should be the same to prevent unevenness between the sides and the middle.

4-7 If necessary, use fine sandpaper to polish the fine parts.

All edging operations must be coordinated with cooling water.

▌5. Cut out

After any opening is lined and positioned, it must be reviewed and confirmed by the team leader before the knife can be lowered. All operations must be accompanied by cooling water.

5-1 The products from the previous process must be inspected for quality, and unqualified products should be rejected.

5-2 Read the drawing size before opening the hole and before drawing the line, pay special attention to the relationship between the center line or the side line, and do not confuse the center line and the side line.

5-3 The opening must be carried out on a wooden workbench with a large surface support. Suspended operation is strictly prohibited to prevent cracks caused by falling off.

5-4 Water tap and gas hole:

Use a hand drill or an impact drill, install a diamond drill bit, fix the wood mold hole on the table, and slowly drill down the wood mold hole.

5-5 Opening of stoves, sinks and basins:

5-5-1 Leave a gap of 3mm on all four sides of the hole, and reserve expansion space for accessories.

5-5-2 After marking the line on the board, in order to avoid the extension of the cutting line and the cracks and appearance of the corners, you must first drill a hole of φ3cm or more in the opening corner, and then use a hand cutter to cut along the inside of the hole and keep it Fillet corners as large as possible.

5-6 Use curved quartz stones to reinforce the four corners of the hole.

5-7 Use 25mm wide stone strips to reinforce around the hole.

All sink holes, basin holes, and furnace holes on the table must be laid with three sinks, that is, 50 #, 150 #, 500 #, to ensure that the opening edge is smooth and free of cracked teeth.

▌6. Chamfer

After any cut corner is lined up and positioned, it must be reviewed and confirmed by the team leader before the knife can be lowered. All operations must be equipped with cooling water. After the line is marked on the board, in order to avoid the extension of the cutting line and the appearance of corner cracks, it is necessary to drill a hole of φ3cm or more in the corner of the cutting corner, and then use a hand cutter to cut along the inside of the hole , And keep the rounded corners as large as possible at the corners. (The back wall can be covered)

Three water mills are required for all cut corners, that is, 50 #, 150 #, 500 #, to ensure that the edge of the opening is smooth without cracking teeth.

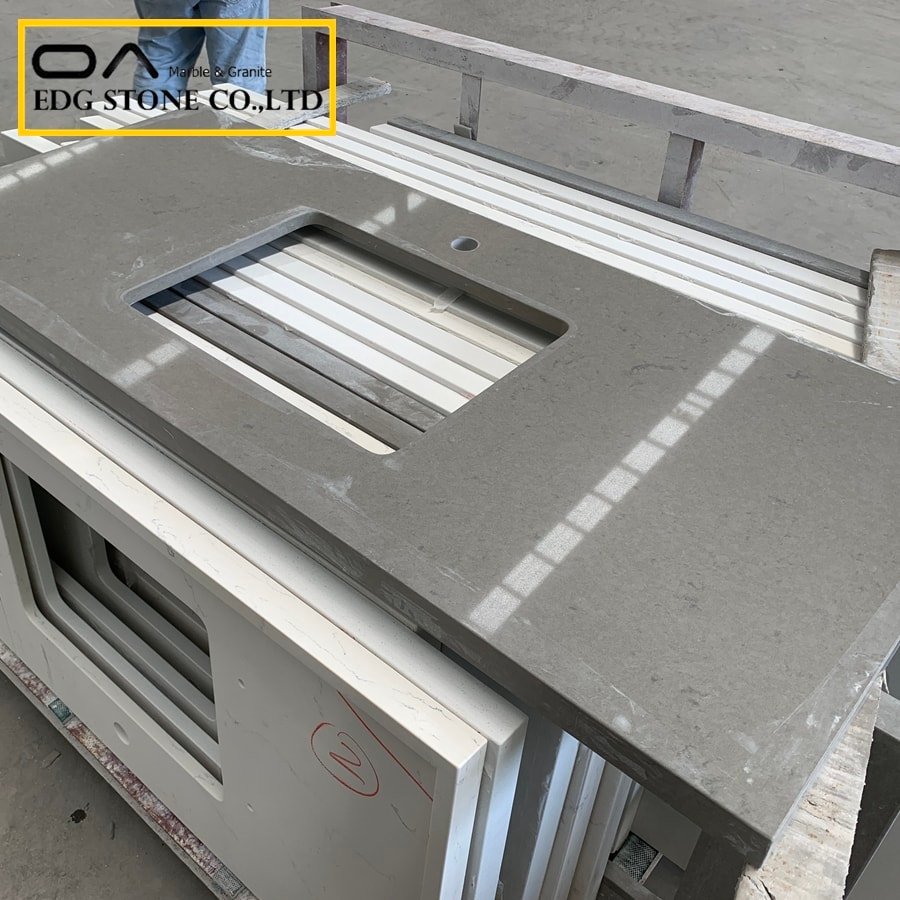

▌7. Under counter basin processing

After the under-counter basin is made with holes, the edges of the test basin will be polished and polished first, and then the edge of the basin and the countertop will be closely combined with color mixing glue (pay attention to the direction of the overflow and drain). Glue, and finally use the same color glue to strengthen the remaining material (long strip) quartz stone at the bottom.

▌8. Processing of flat table top and under-pad cushion

8-1 Quality inspection is required for the products from the previous process, and rejected products should be rejected.

8-2 Read the drawings first, and be aware of the places where wooden strips and planks are needed.

8-3 All the dimensions should be calculated in place when the wooden strips or wooden planks are under the joint surface. Try to use the push table to avoid the use of jigsaws to saw the wooden strips or wooden planks.

8-4 The bottom of the countertop should be cleaned and placed in order before joining with the same color glue to ensure that the wooden pad or wooden pad is tightly combined with the countertop, and the glue on the contact surface is smooth and seamless. If necessary, use a jig to match. For the method of using the jig, see the straight-edge joining specifications. Paste wooden strips at equal distances in front, middle, and back. When the same color glue is about to dry, remove excess residual glue.

8-5 Clean all the stains on the countertop. The countertop that needs to be waxed should be waxed. It can only be stored in the finished product area after being approved by quality inspection.

▌9. Packaging and transportation

9-1 The board is separated by a 2cm foam board to prevent accidental scratches.

9-2 When installing and transporting the finished product, fix it in the car with a wooden frame or angle steel frame, and then bind the finished product to the shelf.

▌10. On-site construction and installation

Ⅰ. Necessary tools for on-site construction and installation

1. Angle grinder (one gold steel grinder)

2. Water mill (resin grinding disc)

3. Hand drill

4. Screwdriver head and gold steel drilling head (φ35, φ25, φ15)

5. Jigsaw

6. Small blade

7. Neutral adhesive (transparent, white)

8. Same color glue (transparent, white)

9. Hardener, toner

10. Triangle glass fixture

11. Wiring socket

12. Film and adhesive tape

Ⅱ. On-site construction and installation

Ⅱ-1 Valuable items such as electrical appliances (range hoods, dishwashers, ovens, refrigerators) that have been installed on site are protected with film adhesive tape first.

Ⅱ-2 Use a horizontal ruler to check the flatness of the on-site kitchen cabinets. When installing, ensure that the bottom surface is absolutely flat. Check whether the tabletop and the on-site dimensions are consistent. If there is an error, correct it.

Ⅱ-3 must ensure a gap of 3.5mm between the edge of the countertop and the wall, and then adjust the installation and the expansion of the thermal expansion and contraction of the countertop, and fill the gap with adhesive glue (glass glue, etc.).

Ⅱ-4 Place the countertop and back wall for local adjustment and decoration, and tap to check if there is any vacancy. Tiny vacancy can be filled with adhesive glue at the bottom. If the surface is severely uneven, stop installation, adjust the kitchen cabinet or repair The table is flat.

Ⅱ-5 Remove the adjusted table top and apply adhesive (glass glue, etc.) to the side plate where the under-bench pads and the kitchen cabinet are connected.

Ⅱ-6 When L-shaped countertops or extra-long countertops need to be joined on the large surface, if necessary, strong glass clamps can be used to clamp two large surfaces and squeeze the gap. The joint must be clean and dry, and the color-adjusted glue should be evenly applied. At the part where the seam is needed, rub the table front and back when placing two tables, press the gap to be small and neat, and ensure the flatness between the two boards. Use a small blade to scrape off the joint after about 10-15 minutes Glue oozing from the seam surface.

In particular, it is not recommended to grind the surface of the seam, especially the dark series, which is absolutely prohibited. Polish the surface and use 100mm wide under the seam to strengthen the warranty.

Ⅱ-7 Use adhesive glue (glass glue, etc.) to bond the back wall, and evenly apply color-adjusted adhesive glue to the bottom of the back wall, place the back wall on the cabinet surface, and then rub the back wall left and right, about 10- Wipe out the glue that oozes out in 15 minutes. Do not use the same color glue to connect the back wall. The bonding glue (glass glue, etc.) has a certain toughness and will not cause cracking or breaking.

Ⅱ-8 Wait for about 10-15 minutes and then use water or detergent to wipe off the excess adhesive.

Ⅱ-9 Avoid opening holes on site as much as possible. If you want to open holes, you must strictly follow the opening methods specified by the company. You must support the bottom and ensure rounded corners. If you want to open a hole, you must stick it to the back wall after the connection is completed.

Ⅱ-10 Use the blade to scrape off the residual glue on the surface and clean it thoroughly.

Ⅱ-11 adhesive glue is usually available in white, black and transparent. For large-surface joints, if the customer really needs to perform surface polishing (light color series), the joint glue can be changed to “dry fast” with the same color glue (brand recommendation: EPOXY). Mildew and antibacterial can reduce the blackening of colloid.