Quartz is a mineral resource with very stable physical and chemical properties. Quartz stone is an abbreviation of the plates produced by the current quartz stone plate manufacturers. Because the main component of the plate is more than 94% quartz, it is called It is quartz stone.

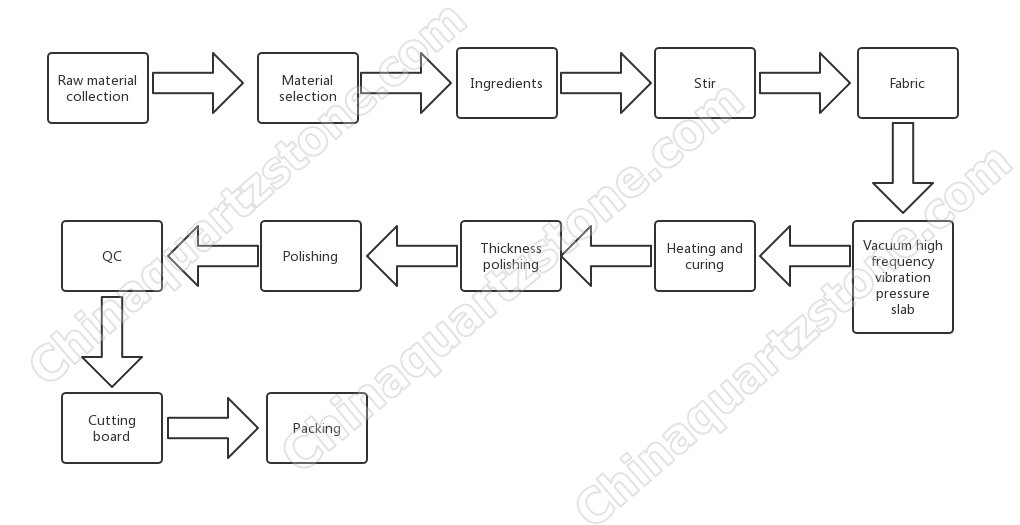

Quartz stone production process:

China quartz stone slab producing lines

Quartz stone process description:

1. Raw material collection: procurement of raw and auxiliary materials such as glass, quartz, and resin.

【Resin】

Resin for quartz stone

【Quartz Sand】

Natural Quartz Sand

2. Material selection: Use fans, iron removal equipment, and manual selection to remove impurities and iron filings from the granular raw materials.

Quartz Sand Material selection

3. Ingredients: After selecting the materials, transport the materials into the mixing system. The materials are fully mixed in the non-gravity mixer to eliminate the problem of material color difference and uneven particle size. After the mixing is completed, it is transported to the corresponding batching bin, and the batching system automatically batches during production.

4. Stirring: Fully stir and mix the unsaturated polyester resin, pigments, additives, and granular powder.

Stirring

5. Cloth: The mixed material that has been stirred enters the cloth car through the conveyor belt, and then the cloth car will evenly spread the material into the cloth mold frame.

Cloth

6. Vacuum high-frequency vibration pressing plate: After the cloth is finished, it is transferred to the press equipment and vibrated, and pressed under the vacuum condition of -0.1MPa.

7. Heat curing and shaping: After pressing, the blank is heated and formed at 85-110℃ in the curing furnace.

Heat curing and shaping

8. Thickness setting and polishing: After the blank is solidified, it is cooled down for 24 hours, and then enters the thickness setting equipment for thickness setting.

9. Polishing: After the thickness is set, it is polished by water milling through a 20-head polishing machine. According to different needs, polish to a gloss of 40-70°.

Quartz Slabs Polishing

10. Inspection: Inspect the appearance quality of the board.

QC Worker Inspection

11. Cutting board: Use vertical and horizontal cutting and bridge cutting equipment to cut the product to the required size.

12. Packing and warehousing: The cut products are air-dried, packaged, and stored in the warehouse.

Packing and warehousing