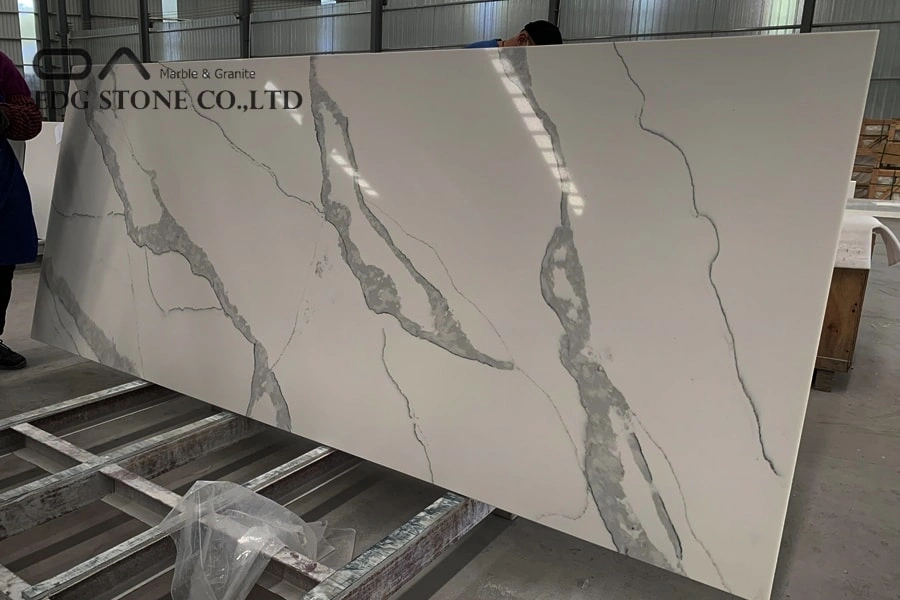

Quartz stone is a kind of artificial stone. It has the characteristics of natural environmental protection, non-toxic, and non-radiation. Because of its natural quartz hardness, tightness, and no pores, and no cracks, quartz stone is sturdy and durable, and the color is elegant and fashionable. The psychological needs of high performance are therefore welcomed and favored by modern decoration. The most familiar is the use of cabinet countertops. Many people have their own methods for distinguishing real and fake quartz stones. And how to accept and test the installed countertops?

1. Impurities, with a 50㎝ direct visual inspection, are not allowed to exceed 3 impurities per square meter, each particle is less than 0.5 mm in diameter and has no concentrated distribution, and raw variegated particles of the same mesh number are allowed to be 3-5 per square meter.

2. The air bubbles on the table are also visually inspected with a 50cm face, and no air bubbles are allowed on the front of the table.

3. Cracks, visually inspected with a 50cm face, the surface of the table has no cracks, no broken, and obvious crack repair marks.

4. Visual inspection of the color, the plate used for the same set of countertops is not allowed to have a color difference, and the color deviation from the model should not be too large.

5. Visual inspection of scratches, table chamfering, and smooth surface, no scratch marks.

6. Visual inspection of the line shape shows that the line shape of each set of countertops is clear and smooth, and the waterproof line has no cracks, no obvious unevenness, and visible processing marks.

7. Use a level ruler for size, the table should be flat, no waves should appear, and the size error should be less than ±3mm.

8. Visual inspection of the appearance, the gloss of the countertop is basically the same, the appearance is neat and clean, and there is no stain. The finish is 55±5 degrees using a finished gauge.

9. Visual inspection of the connection point shows that the connection line of the countertop is straight, smooth, without glue watermark, and the bottom of the connection port is reinforced with a gasket (due to the material characteristics of quartz stone products, there are no obvious connection marks at the connection point).

10. Visual inspection of the pothole shows that the pot and the table are combined smoothly, the positive and negative rubber materials are full and firm, and the bonding line is straight and beautiful. The wall of the furnace hole is straight, without obvious processing marks, the surrounding arc transitions naturally, and the four corners of the furnace hole must be bonded to strengthen the support.